EXCITING NEWS – we are the official representatives of TMC in Israel

31.03.2024

We wanted to share this exciting news that we are now the official representatives of TMC in Israel 📢💥

-

TMC designs and manufactures advanced building floor vibration isolation systems for nanotechnology.

-

TMC isolators support ultra precision measurements, instruments, and manufacturing. they are to leading the industry with sophisticated active, inertial vibration cancellation systems featuring piezoelectric actuators and digital controllers.

-

TMC passive products range from simple, desktop isolated microscope bases, to virtually any size optical table systems.

-

TMC products enable ultra-precision research, measurements, and manufacturing in the fields of photonics, semiconductor manufacturing, life sciences, drug discovery, and nanotechnology.

-

TMC products are designed and manufactured at our state-of-the-art, vertically integrated manufacturing facility and are backed by a customer commitment to provide superior global service.

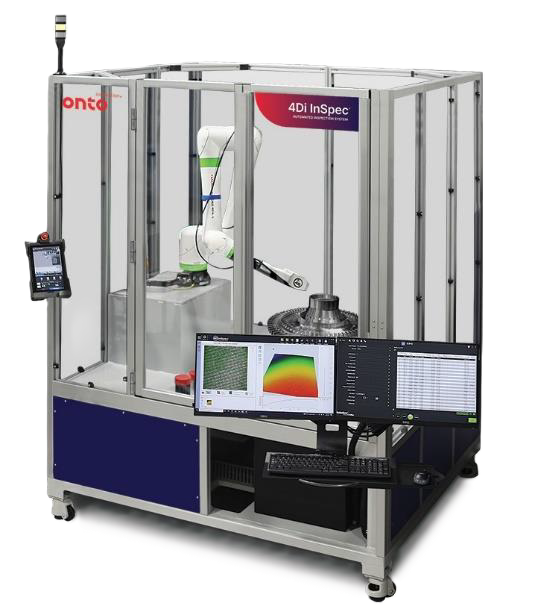

OptiPro Systems Receives 2024 Innovative System of the Year Award from FANUC America

14.03.2024

OptiPro Systems Receives 2024 Innovative System of the Year Award from FANUC America

Automated defect and feature metrology system enables new levels of quality and reduced rework for aerospace components further enabling aviation safety standards.

Ontario, NY – February 29, 2024 – OptiPro Systems, LLC, a FANUC Authorized Systems Integrator (ASI) and leading manufacturer and distributor of precision CNC machines and CAD/CAM software, has announced that they have been named winner of FANUC America’s 2024 Innovative System of the Year award for the 4Di InSpec automated metrology system (AMS). In partnership with 4D Technology, OptiPro developed the high-throughput, high resolution defect and feature inspection solution. A FANUC collaborative robot and custom metrology automation software developed by OptiPro enables the system to measure dozens of edge break features, chamfers, and radii in minutes rather than days. By implementing this solution, a manual operation that took multiple weeks to make 400 measurements was reduced to a matter of minutes.

“This award is a reflection of the incredible automation team we have at OptiPro,” said Rob Bechtold, President of OptiPro Systems. “As a FANUC Authorized Systems Integrator, OptiPro is dedicated to providing robotic automation solutions that help manufacturing companies achieve new levels of excellence. This robotic solution is a prime example of our ability to collaborate with manufacturers looking to automate processes that lead to more efficient production.”

The automated metrology system can be configured for multiple applications, including large, rotary applications, small freeform components such as turbine blades and multi-sensor applications. It is powered by OptiPro’s RoboQual™ custom metrology automation software. RoboQual™ bridges communication between the robot and the measuring device while adding an easy-to-use interface that compiles all measurement data files in one location. After identifying acceptable tolerances during job setup, RoboQual™ analyzes each measurement value and intuitively determines whether the measurement passes or fails. Users can also generate a report from RoboQual™ that contains all measurement data and pass/fail information. The solution is equipped with a FANUC CRX 10iA/L collaborative robot that is easier to program through custom software shortcuts developed by OptiPro’s automation team.

Learn more about OptiPro’s Automation Solutions by visiting Automation Solutions – OptiPro Systems

For more information about the 4Di InSpec automated metrology system, visit the 4D Technology website.

4Di InSpec Automated Metrology System

05.03.2024

Onto Innovation’s 4Di InSpec™ Automated Metrology System Receives 2024 Innovative System of the Year Award from FANUC America

Automated defect and feature metrology system enables new levels of quality and reduced rework for aerospace components further enabling aviation safety standards

Wilmington, Mass., February 26, 2024 – Onto Innovation Inc. (NYSE: ONTO) and its Tucson subsidiary 4D Technology today announced they’ve been named winner of FANUC America’s prestigious 2024 Innovative System of the Year award for the 4Di InSpec automated metrology system (AMS). The system enables automated surface defect and feature metrology for aviation, aerospace and other applications in the industrial manufacturing market. The patented, vibration-immune technology enables the unique capability of using non-contact, three-dimensional optical metrology on the production floor, providing new levels of defect inspection with micrometer-level resolution. In partnership with OptiPro Systems, the 4Di InSpec AMS systems were delivered in the second half of 2023 to several leading aerospace engine manufacturers.

“We are honored to be recognized as an innovator by a robotic industry leader like FANUC America,” said Erik Novak, vice president and general manager of Onto Innovation subsidiary 4D Technology. “The combination of FANUC robotics with 4Di non-contact sensor technologies provides a unique platform for improving throughput, quality and delivery times in industrial manufacturing. We look forward to the continued expansion of our automation metrology portfolio to help our customers solve some of the more complex industrial manufacturing challenges in the industry.”

The aviation industry is focused on safety amid the ongoing labor shortage post-pandemic, driving a renewed emphasis for an increase in quality control and improved labor utilization. Currently, visual inspection of engines is the standard quality control practice, including repro-rubber and shadowgraph off-line techniques, which are time-consuming and subjective. The industry can utilize the 4Di InSpec automated metrology solution to achieve significantly higher sampling rates and improved quality control while providing fast, accurate and reproducible results. The automated system is capable of measuring 400 typical engine call-out measurements in under 30 minutes, which can take weeks using traditional methods, enabling manufacturers to reallocate labor for

other critical tasks.

The technology has demonstrated the ability to reduce scrap and rework by up to 40% on engine components.

The 4Di InSpec AMS can be configured for multiple applications, including large, rotary applications, small freeform components such as turbine blades and multi-sensor applications. Bob Wasilesky, senior director of sales and marketing for Onto Innovation subsidiary 4D Technology, said, “Multi-sensor, automated systems are the next step to delivering increased value to our customers, where one robot, with dual sensors, can measure surface roughness, surface features and defect inspection all in one system, greatly increasing efficiencies.” To learn more about Onto’s 4Di InSpec automated metrology system, visit the 4D Technology website or contact us.

About 4D Technology

4D Technology, an Onto Innovation subsidiary, is a global leader in the design and manufacture of vibration-insensitive, portable and automated dynamic laser interferometers, optical profilers, and optical surface gauges. Our systems provide precise measurement of surface features, roughness, and defects — even in the most challenging environments. Serving: precision machined surfaces, optics, astronomy, aerospace and defense, space-based telescopes, optical communications, automotive, and in-line production measurements.

About Onto Innovation Inc.

Onto Innovation is a leader in process control, combining global scale with an expanded portfolio of leading-edge technologies that include: Un-patterned wafer quality; 3D metrology spanning chip features from nanometer scale transistors to large die interconnects; macro defect inspection of wafers and packages; metal interconnect composition; factory analytics; and lithography for advanced semiconductor packaging. Our breadth of offerings across the entire semiconductor value chain combined with our connected thinking approach results in a unique perspective to help solve our customers’ most difficult yield, device performance, quality, and reliability issues. Onto Innovation strives to optimize customers’ critical path of progress by making them smarter, faster and more efficient. With headquarters and manufacturing in the U.S., Onto Innovation supports customers with a worldwide sales and service organization. Additional information can be found at www.ontoinnovation.com.

Forward Looking Statements

This press release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995 (the “Act”) which include statements relating to Onto Innovation’s business momentum and future growth; the benefit to customers and the capabilities of Onto Innovation’s products and customer service; Onto Innovation’s ability to both deliver products and services consistent with our customers’ demands and expectations and strengthen its market position, Onto Innovation’s beliefs about market opportunities as well as other matters that are not purely historical data. Onto Innovation wishes to take advantage of the “safe harbor” provided for by the Act and cautions that actual results may differ materially from those projected as a result of various factors, including risks and uncertainties, many of which are beyond Onto Innovation’s control. Such factors include, but are not limited to, the Company’s ability to leverage its resources to improve its position in its core markets; its ability to weather difficult economic environments; its ability to open new market opportunities and target high-margin markets; the strength/weakness of the back-end and/or front-end semiconductor market segments; fluctuations in customer capital spending; the Company’s ability to effectively manage its supply chain and adequately source components from suppliers to meet customer demand; the effects of political, economic, legal, and regulatory changes or conflicts on the Company’s global operations; its ability to adequately protect its intellectual property rights and maintain data security; the effects of natural disasters or public health emergencies, such as the COVID-19 pandemic, on the global economy and on the Company’s customers, suppliers, employees, and business; its ability to effectively maneuver global trade issues and changes in trade and export regulations and license policies; the Company’s ability to maintain relationships with its customers and manage appropriate levels of inventory to meet customer demands; and the Company’s ability to successfully integrate acquired businesses and technologies. Additional information and considerations regarding the risks faced by Onto Innovation are available in Onto Innovation’s Form 10-K report for the year ended December 31, 2022, and other filings with the Securities and Exchange Commission. As the forward-looking statements are based on Onto Innovation’s current expectations, the Company cannot guarantee any related future results, levels of activity, performance or achievements. Onto Innovation does not assume any obligation to update the forward-looking information contained in this press release, except as required by law.

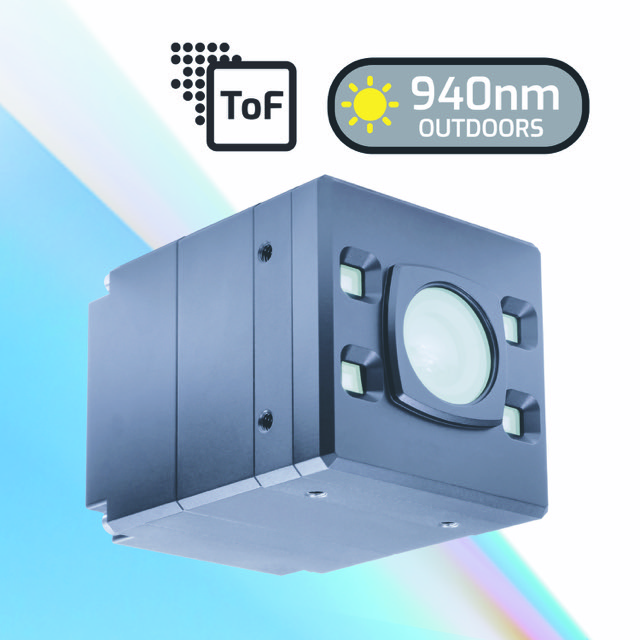

LUCID Unveils Helios™2 Ray Time-of-Flight Camera Designed for Unmatched Performance in Outdoor Lighting Conditions

17.01.2024

LUCID announced the series production of the new Helios™2 Ray Outdoor Time-of-Flight (ToF) camera.

The Helios2 Ray camera is powered by Sony’s DepthSense IMX556PLR ToF image sensor and is

specifically engineered for exceptional performance in challenging outdoor lighting environments.

Equipped with 940nm VCSEL laser diodes, the Helios2 Ray generates real-time 3D point clouds, even in

direct sunlight, making it suitable for a wide range of outdoor applications. The Helios2 Ray offers the

same IP67 and Factory Tough™ design as the standard Helios2 camera featuring a 640 x 480 depth

resolution at distances of up to 8.3 meters and a frame rate of 30 fps.

“We’re excited to expand our acclaimed Helios2 Time-of-Flight camera family with the purpose-built

Helios2 Ray, tailored explicitly for outdoor lighting conditions,” says Rod Barman, Founder and President

of LUCID Vision Labs. The Helios2 Ray excels across a diverse range of outdoor applications, including

agriculture, depalletization, environmental monitoring, and infrastructure inspection.”

LUCID’s proprietary Arena SDK integrates user-friendly controls for all Helios2 ToF cameras. The

ArenaView GUI enables users to visualize scene intensity and depth in either 2D or 3D point cloud views,

offering real-time manipulation and orientation. Additionally, the software facilitates on-the-fly

adjustments, including false color overlay and depth range modifications.

All LUCID cameras conform to the GigE Vision 2.0 and GenICam3 standards and are supported by LUCID’s

own Arena software development kit. The Arena SDK provides customers with easy access to the latest

industry standards and software technology. The SDK is compatible with the Windows, Linux 64-bit, and

Linux ARM operating systems, and supports the C, C++, C# and Python programming languages.

The Helios2 Ray HTR003S-001 camera is list priced at $1,495 USD and is now available to order.

For more information, please visit our Helios2 Ray product page

LUCID Interduce the New Triton2 – 2.5GigE Camera Featuring Gpixel’s GMAX4002 Sensor with Enhanced Near-Infrared (NIR) Sensitivity

30.11.2023

LUCID announced the series production of its latest Triton2 – 2.5GigE camera featuring Gpixel’s GMAX4002 sensor with enhanced NIR sensitivity.

The Triton2 TRT024G camera leverages LUCID’s proven 2.5GigE industrial platform paired with Gpixel’s GMAX4002 NIR-enhanced global shutter CMOS image sensor. This new 2.4 MP sensor, designed around a 4 µm charge domain global shutter pixel, offers a 2048(H) x 1200(V) resolution within a 1/1.7” optical format. Each 4 µm pixel achieves a full well capacity of 12k e-, read noise less than 3 e-, and a maximum dynamic range of 68.5 dB in 12-bit mode. Advanced pixel design and manufacturing techniques have yielded exceptional performance, including a peak Quantum Efficiency (QE) of 72% at 550 nm and over 37% at 850 nm, thanks to Gpixel’s Red Fox NIR enhancement technology.

The Triton2 camera features a Factory Tough™ IP67-rated industrial platform, delivering unparalleled performance within a compact, cost-effective, and uncompromising camera design. The integration of a 2.5GigE (300 MB/s) interface enhances bandwidth, while retaining the benefits of a compact size, efficient thermal management, and Power over Ethernet (PoE) support.

“With the continued expansion of our Triton2 – 2.5GigE camera family, we’re providing a comprehensive range of image sensors and resolutions to cater to a diverse range of applications,” says Rod Barman, Founder and President of LUCID Vision Labs. “The Triton2 featuring Gpixel’s GMAX4002 offers enhanced NIR sensitivity, and its wide aspect-ratio 2.4 MP resolution is well suited for applications such as fruit sorting, ANPR, and logistics.”

Designed for seamless integration, the 2.5GBASE-T Triton2 enables rapid data transfer rates of 300 MB per second and supports standard CAT5e and CAT6 cables up to 100 meters.

All LUCID cameras conform to the GigE Vision 2.0 and GenICam3 standards and are supported by LUCID’s own Arena software development kit. The Arena SDK provides customers with easy access to the latest industry standards and software technology. The SDK supports the Windows, Linux 64-bit and Linux ARM operating systems, and the C, C++, C# and Python programming languages.

The new Triton2 TRT024G model is now available for order. For more information, please visit our Triton2 product page

SPIE PHOTONICS WEST , SAN FRANCISCO, CALIFORNIA, USA 27 JANUARY – 1 FEBRUARY , 2024

13.11.2023

SPIE PHOTONICS WEST 27 JANUARY – 1 FEBRUARY , 2024

SPIE Photonics West Exhibitions – Gain access to four world-class exhibitions: 1,500+ companies

Find the best solutions, components, instruments, and system providers from around the world. Meet top suppliers and discover new possibilities.

The free exhibition visitor badge provides entry into all exhibitions during the week of SPIE Photonics West. Registration also includes industry programming to grow your business insights and your professional network. See details below and ensure you and your team have a plan to see it all.

If you plan to attend, let us know so we can set meetings for you with our suppliers around the world.

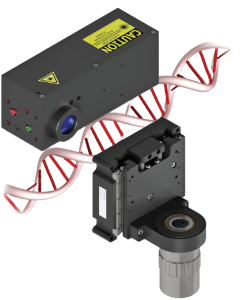

Introducing The New PFA-DT Autofocus Sensor by WDI

22.10.2023

Introducing The New PFA-DT Autofocus Sensor by WDI

Discover the future of Precision Focus Automation with our latest addition to the world’s most powerful microscopy autofocus sensors: the PFA-DT. Driven by the demands of the biomedical industry for fast and accurate autofocus solutions, WDI has developed and refined its PFA sensor family technology to create PFA-DT. The new sensor offers remarkable improvements in speed, accuracy, processing and communication, all at a very affordable price.

Key Features and Benefits:

-

Up to 8 KHz update rate and faster processing result in improved high-speed tracking performance.

-

Significant upgrades in memory, processing power, and functionality improve the sensor’s adaptability and programmability.

-

The PFA-DT features a configurable output supporting both analog output and digital step and direction, making it a universal solution that can interface with Piezo actuators, Dover Motion’s DOF-5, WDI PFABUS ZAAs and other third party Z axis stages.

-

Offset Adjuster (OA) lens versions available to account for variations between the sensor focal plane and camera imaging plane.

-

Real-time diagnostic and performance reporting with insightful analytics and statistical metrics.

-

Gigabit Ethernet communication and Linux OS provide greater reliability and enhanced capabilities.

-

Available laser wavelengths include 660nm, 785nm, 850nm.

- Gigabit Ethernet communication and embedded Linux OS provide greater reliability and enhanced capabilities.

New Application and product Videos | ALIO

27.07.2023

New Application and product Videos | ALIO

9 new videos added (also available via our YouTube channel): https://alioindustries.com/library/videos/

Please specifically check out the excellent videos made by Colombian Imaging Technologies and HPPI:

-

https://alioindustries.com/video/customer-application-colombian-imaging-technologies-cheetah-advanced-high-speed-microlithography-for-holographic-packaging-and-security-masters/

-

https://alioindustries.com/video/customer-application-hppis-fully-automated-2-pin-probing-solution-for-hbm-tlp-hmm-and-cc-tlp-on-package-and-wafer-level