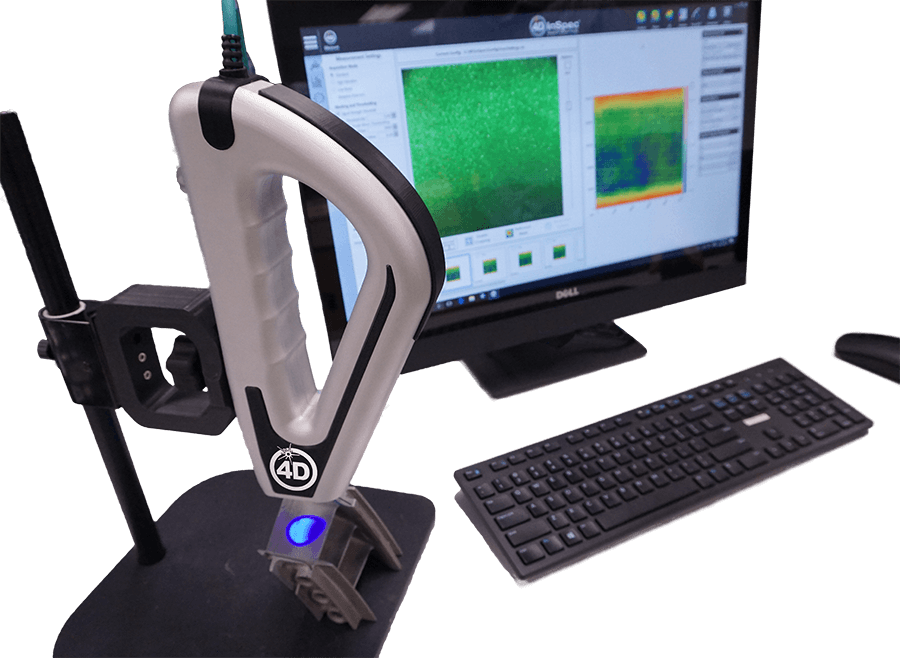

The 4D InSpec Surface Gauge is the first handheld, precision instrument for non-contact measurement of surface features and

defects. With micrometer-level resolution, portability, affordability and ease-of-use, 4D InSpec puts high resolution measurement on

the factory floor, in machine shops and deployed environments.

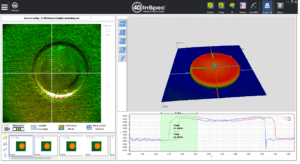

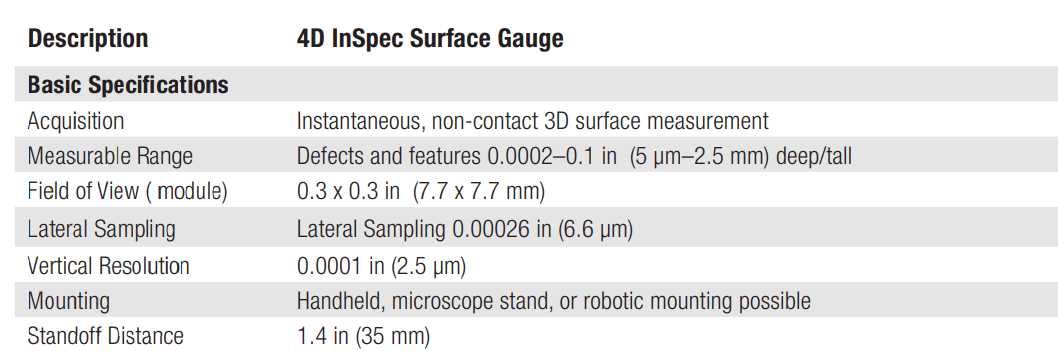

4D InSpec brings 3D measurement to the factory floor, to quantify pits, scratches, nicks, dents, bumps, porosity and other features from 0.0002” to 0.1” (5 µm–2.5 mm) deep or tall. 4D InSpec is far more repeatable and accurate than visual comparison techniques typically used for surface defect measurements. Unlike high-end

metrology systems it is rugged, flexible and affordable, to measure a wide range of part geometries in the most challenging environments